Try Amazon Audible Premium Plus and Get Up to Two Free Audiobooks

FLYING THE PROTOTYPES

|

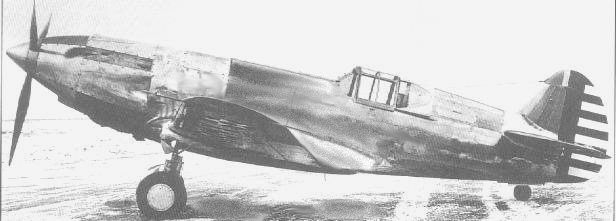

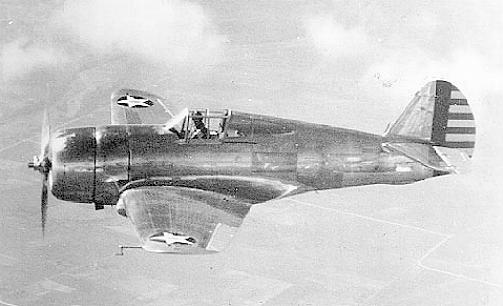

The YP-37 built by Curtiss was the first Army Air Corps fighter plane to use the Allison V-l710-11 engine. The airframe from the Curtiss P-36, an airplane already in production, was used to build the XP-37.

|

My first flight in the YP-37A was damn exciting. Since there were no pilots at Langley who had flown the YP-37A, I had to rely on the aircraft's operating flight manual. I studied it for several hours, then sat in the cockpit for more than an hour to familiarize 'myself with the controls and instruments. I felt as ready to go as I would ever be, I started the engine and taxied out to the northwest runway, Langley's longest, for my first flight.

|

It was too late to land, since there was no runway left. There was little I could do except throttle back and try to cool the engine. Normally, reducing power would help. I had hoped I could circle the field and land back on the runway, with the reduced power.

|

A quick glance at the speed indicator just at lift-off showed sixty mph. I knew It was in error, but my attention had been distracted by a more pressing problem. Normally, an inoperative airspeed indicator didn't present any difficulty, if I could have climbed upstairs and got to know the airplane before making a landing. At that moment, I had a grand total of two minutes in the YP-37A, hardly time enough to become comfortable with the airplane. On the downwind leg, the speed showed only eighty, though I knew it had to be closer to one hundred fifty, since this airplane stalled at eighty five miles per hour.

With my head stuck out the side of the cockpit, I still couldn’t see very well and didn’t know how fast I was going. The landing was going to he a tough one. I had to call on my overworked Guardian Angel once again.

I contacted the control tower, "May Day, I have an emergency and must land immediately."

"Cleared to land. The crash crew is on the way."

I was able to get out a brief, "thanks," and then concentrated my attention on flying the airplane. I circled back for landing and stayed within gliding distance of the field in case the engine quit. I could at least turn toward the field and belly land on the grass. Without the benefit of knowing the speed, I played it safe and came in a little hot. Fortunately, I had plenty of runway, and my landing was okay, but having my head stuck out of the cockpit made it very difficult. I slowed down and turned off the runway. When clear, I stopped in the grass and cut the engine. I could hear it crackling from the heat, so I jumped out in case it caught fire. If it did, I would have a head start and be long gone when it happened. While I waited nearby for the crash vehicles to arrive, I had time to thank my special Angel. I knew I would be lost without him. When the ambulance pulled up, I jumped in and was taken to base operations.

I found out later the airplane had been undergoing flight tests at NACA (National Advisory Committee on Aeronautics), and at the completion of the tests it was turned over to Base Engineering. The tests they were conducting were a series of flights that required the installation of specially calibrated test instruments. The airspeed indicator, of course, was among them. When they removed their instrumentation, NACA forgot to cap off the "T" they used that was part of the airplane's original pitot system which showed the plane's airspeed. This was the reason for the very low airspeed indication.

|

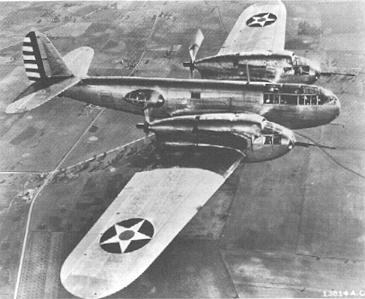

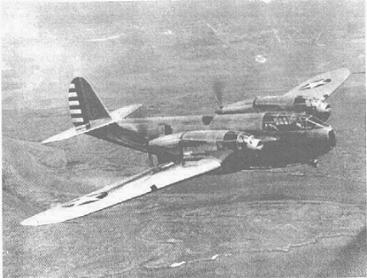

Another

airplane I flew was the YFM-1 Airacuda, made by Bell Aircraft

Corporation in Buffalo, New York. It was a pusher built around two

exhaust-driven turbo-charged Allison engines of 1040 horsepower each. It

was new in type and concept. The design's hypothesis was that it would

he used as a bomber-destroyer. It had thirty-seven millimeter cannons,

one in the nose of each nacelle, but little in the way of defensive

weapons. Several other innovations were being explored on the Airacuda

that were not used on any previous military airplanes. Because some of

the innovations were impractical, they haven’t been used since.

|

Flying the Bell Airacuda was a new experience for me, since it was the

first pusher aircraft I'd ever flown. Its handling characteristics were

foreign to anything I had ever had my hands on. Under power it was

unstable in pitch, but stable with power off. While flying straight and

level, if a correction in pitch was required, a forward push on the

control resulted in the airplane wanting to pitch over even more. Pitch

control became a matter of continually jockeying the controls, however

slightly, even when the aircraft was in proper trim. The same applied if

pulling back on the control. It would tend to continue pitching up,

requiring an immediate corrective response. The same happened in a turn

with power off, the Bell became stable in pitch. This was fortunate

because during approach and landing, it was very stable, and a nice

flying airplane.

|

It was built around several new ideas never tried before, and was unlike

any other fighters up to that time. First, it wasn't designed to be a

fighter plane, although many had the mistaken idea that it was. It could

be better described as a bomber destroyer. The tactics suggested by its

designer were based upon the machine being used as a flying

anti-aircraft platform. It was a defensive weapon to be used only

against incoming bombers that were beyond The range of escorting

fighters. Although it had some defensive weapons, I think they were more

psychological in nature, for the benefit of the YFM-1 crew, than

practical.

The tactics envisioned were that the Airacuda would fly in trail, just

out of range of the enemy bomber formation's guns. Up to that time

bombers had .30 and .50 caliber weapons. It is important for the reader

to keep in mind that the Bell would be used only against enemy bomber

formations that were out of range of protective fighter escort. The

YFM-1 had little or no effective firepower for its defense, and as a

consequence, would be a sitting duck against agile fighters. The front

of each engine nacelle housed a 37 mm, gyro-stabilized cannon. With the

longer range of the 37 mm guns, they could pluck the enemy bombers off

one by one, In other words, it was a mobile anti-aircraft gun platform.

|

The primary function of the men in the nacelles was loading the guns,

although they could be fired by the gun crew in an emergency. Initially,

the pilot of the plane aimed the airplane in the general direction of

the formation. Further correction in aim would then be made by the gun

control officer, and fired by him. His station was directly behind the

pilot, using an inverted periscope that came out through the belly of

the ship to aim the guns. The fire control officer would clutch the guns

into the gyros, which stabilized them. From that moment on they would

stay on target. The person operating the guns could then make any

further correction and fire away until the bomber was brought down. His

position had swing-out flight controls and in an emergency he could fly

the airplane. If it was necessary to abandon the aircraft, the pilot

would have to feather both engines to prevent the propellers from

chewing the men to pieces, especially those in the nacelles The flight

manual said they would feather in six seconds; that's a long time in my

book.

In addition to being a pusher airplane, the YFM-1 also had other unusual

features. It had only one engine-driven accessory, an emergency

fifty-ampere generator on the left engine. The Bell Airacuda was an

electrical nightmare. All normally driven engine accessories such as

fuel pumps, hydraulic pumps, vacuum pump, and the gyros stabilizing the

guns were electrically driven. Because of all the electrical energy

required, the ship had to have a full-time auxiliary power unit. The

auxiliary power unit was driven by a powerful four cylinder gasoline

engine which ran all the equipment. Since the aircraft was required to

operate at high altitudes, the APU also had to be turbo-supercharged. To

do this, a dual bleed came from the same exhaust turbochargers that

super-charged the Allison engines. The power unit was the weak link in

the system.

|

Changing fuel

tanks was simple. There was no fuel selector as we normally think of

one. Each fuel tank had its own fuel pump. Tanks were changed by

flipping the switch on for the electric fuel pump of the desired tank.

The gear and flap selector was similar in appearance to the C-47's fuel

selector. Gear and flaps were activated by rotating this control to the

appropriate position. It only had three positions, takeoff, fly and

land, and could be turned only in a clockwise direction. In the takeoff

position, the flaps were retracted. In the fly position, the gear was

retracted, and in the land position, both gear and flaps came down. The

flaps immediately followed the gear. Unfortunately the two were not

isolated from each other, and that posed a minor problem.

To get gear only, such as on downwind, the pilot would watch the gear as

it extended. When almost all the way down, he tripped the circuit

breaker. Then on final, when the flaps were required, the breaker was

turned back on. At the completion of the landing roll, the pilot would

select fly position, retracting the flaps.

The engines had no cooling fans, so in summer the airplanes had to be

towed to the takeoff position before starting. As soon as there was an

indication of an oil temperature rise, the pilot immediately started the

takeoff run. When landing, if the oil temperature was on the high side,

the pilot would have to shut the engines down and have the ship towed

to the parking area. If the airplane had only a short distance to taxi,

it could continue to its parking place under its own power.

One recurring problem experienced by pilots flying the Airacudas was

that the auxiliary power unit would all too frequently stall or quit.

The reverse current relay would stick and motorized the generator. Since

this would drain most of the current from the battery, all electrical

systems became inoperative: NO fuel pressure, NO vacuum, NO hydraulic

pressure, NO gear, NO flaps and NO ENGINES. The first time I lost both

engines, I was in the landing pattern on base leg just about to turn

final when the APU quit, then a second later so did both Allison

engines.

Fortunately, it occurred right after the gear locked down, and I was

able to make the runway without power. Although the airplane had a

wobble pump, the handle was only four inches long. It was impossible to

supply two Allison engines with the wobble pump, since they consumed

over three hundred gallons of fuel per hour at full power. Its only

purpose was to start the engines.

The second time the problem occurred, I was flying on instruments, but

again I was fortunate. They both quit not too long after I had started

into the overcast. I knew there was a couple thousand foot ceiling under

the cloud base, so I dove out of the cloud before the gyros tumbled.

All the while, the crew chief was trying to restart the APU, which

started with room to spare. With the APU going, the fuel pumps came on

and both Allison engines began producing power. The remainder of the

trip to Langley was uneventful and I made a safe landing there.